⚡ Quick Reference: Apron Material Comparison at a Glance

| Material Type | Durability | Comfort | Price Point | Best For |

|---|---|---|---|---|

| Cotton Twill | High | High | Moderate | Professional kitchens, daily use |

| Polyester/Cotton Blend | Very High | Moderate | Low-Moderate | High-volume operations, quick turnover |

| 100% Cotton | Moderate | Very High | Moderate-High | Premium restaurants, comfort-focused |

| Canvas | Very High | Moderate | Moderate | Industrial, workshop, heavy-duty use |

| Polyethylene-Coated | High | Low | Low | Chemical resistance, specialty environments |

🎯 What Makes a Professional-Grade Apron?

- Premium Materials: Professional aprons use high-quality fabrics like cotton twill or poly-cotton blends that withstand frequent washing.

- Reinforced Construction: Double-stitched seams and bar-tacking at stress points ensure long-lasting durability.

- Proper Fit: Adjustable neck straps and long waist ties accommodate different body types comfortably.

- Functional Design: Multiple pockets, appropriate length, and ergonomic features support worker productivity.

📊 Apron Market Snapshot 2025

Global Market Size: USD $2.5 billion in 2023, projected to reach USD $4.1 billion by 2032

Growth Rate: Approximately 5-6% CAGR across most segments

Key Drivers: Hospitality sector expansion, stricter food safety regulations, and growing demand for customization

Top Materials: Cotton/poly blends (42%), polyester (28%), canvas (18%), specialty fabrics (12%)

Whether you’re managing a restaurant chain, outfitting a healthcare facility, or running an industrial operation, choosing the right apron is more than just picking protective wear. In fact, the right apron selection can significantly impact worker comfort, safety compliance, and your bottom line. Therefore, this comprehensive guide walks you through everything you need to know about professional aprons in 2025.

Understanding Professional Aprons: What Sets Them Apart

Professional aprons differ dramatically from casual home-use versions. Specifically, commercial-grade aprons undergo rigorous testing and meet strict industry standards. Moreover, they’re designed to withstand the demands of daily business operations.

What Counts as a Professional-Grade Apron: Materials, Durability, and Fit

A professional-grade apron meets three critical criteria. First, it uses materials that can endure repeated industrial washing cycles. Second, it features construction techniques that prevent premature wear. Third, it provides proper fit and coverage for the intended work environment.

Professional aprons typically include these features:

- Heavy-duty fabrics: Minimum 7-9 oz fabric weight for kitchen use

- Reinforced stress points: Bar-tack stitching at pockets and tie attachment points

Colorfast dyes:

- Maintain appearance after 50+ wash cycles

- Proper sizing options: Multiple size ranges to fit diverse teams

- Industry-specific features: Chemical resistance for labs, heat resistance for grills

Key Differences Between Commercial and Home-Use Aprons

Commercial aprons are built for punishment. Unlike home aprons, they face daily challenges including:

| Feature | Home-Use Aprons | Commercial Aprons |

|---|---|---|

| Washing Frequency | 1-2 times per week | Daily or multiple times per shift |

| Fabric Weight | 4-6 oz | 7-12 oz |

| Expected Lifespan | 2-3 years | 6-12 months with heavy use |

| Stain Exposure | Light to moderate | Heavy, constant exposure |

| Safety Standards | Not required | Must meet industry regulations |

Industries That Rely on Quality Aprons

Professional aprons serve critical functions across multiple industries. Consequently, each sector has unique requirements:

Hospitality and Food Service: Restaurants, hotels, catering companies, and cafes depend on aprons for hygiene compliance. Furthermore, branded aprons create visual consistency across staff members.

Healthcare: Medical facilities, dental offices, and care homes require aprons that meet sanitation standards. Importantly, these aprons often need FDA-approved materials for patient safety.

Industrial and Manufacturing: Workshops, factories, and production facilities need heavy-duty protection. Similarly, these environments often require OSHA-compliant protective wear.

Retail and Craft: Butcher shops, bakeries, craft stores, and artisan workshops benefit from aprons that balance protection with presentation.

Materials That Matter: Choosing the Right Fabric for Your Needs

Material selection is arguably the most important decision when sourcing professional aprons. Indeed, the right fabric determines durability, comfort, maintenance costs, and worker satisfaction. Let’s explore each option in detail.

Durable canvas chef aprons available in custom colors

Durable canvas chef aprons available in custom colors

Waterproof PU-coated aprons for wet environments

Waterproof PU-coated aprons for wet environments

Custom branded aprons with logo printing

Custom branded aprons with logo printingCotton Twill Aprons: Pros and Cons

Cotton twill remains a popular choice for professional kitchens. Specifically, this diagonal weave pattern creates a strong, durable fabric that resists tearing.

Advantages of Cotton Twill:

- Excellent breathability: Keeps workers comfortable during long shifts

- Natural absorbency: Quickly absorbs minor spills before they spread

- Professional appearance: Maintains crisp look after proper pressing

- Good durability: Withstands 50+ industrial wash cycles

- Eco-friendly option: Biodegradable natural fiber

Considerations:

- Requires prompt stain treatment for oil-based substances

- May shrink 3-5% if not pre-shrunk during manufacturing

- Higher initial cost compared to synthetic blends

- Needs proper care to prevent wrinkling

“Cotton twill aprons offer the perfect balance of comfort and durability for most professional kitchen environments. However, pairing them with proper stain pre-treatment procedures extends their lifespan significantly.” – Textile Industry Report 2024

Polyester/Cotton Blend Aprons: The Balanced Choice

Poly-cotton blends (typically 65% polyester, 35% cotton) have become the industry standard. Moreover, they combine the best properties of both fibers while minimizing drawbacks.

Why Blends Work:

- Superior washability: Maintains shape and color through 100+ wash cycles

- Wrinkle resistance: Reduces or eliminates ironing requirements

- Quick drying: Reduces laundry turnaround time

- Cost-effective: Lower price point than 100% natural fibers

- Stain resistance: Synthetic content helps repel oil-based stains

- Color retention: Excellent colorfastness ratings

According to Textile World Magazine, poly-cotton blends account for approximately 42% of all commercial apron production globally. Furthermore, this percentage continues to grow as more businesses prioritize low-maintenance options.

💡 Industry Insight: Many Chinese manufacturers, including specialized apron suppliers, have perfected poly-cotton blend formulations. Consequently, these manufacturers can offer customized blend ratios to match your specific durability and comfort requirements.100% Cotton Aprons: When Comfort Comes First

Premium restaurants and upscale establishments often choose 100% cotton aprons. Specifically, these aprons prioritize worker comfort and present a natural, high-end appearance.

Pure Cotton Benefits:

- Maximum breathability: Ideal for hot kitchen environments

- Soft hand feel: Most comfortable option for all-day wear

- Natural appearance: Premium aesthetic for customer-facing staff

- Excellent absorbency: Handles moisture effectively

- Environmentally responsible: Fully biodegradable and renewable

Trade-offs:

- Requires more frequent replacement (typically 6-9 months)

- Needs careful stain management protocols

- Higher per-unit cost

- More labor-intensive care requirements

Specialty Materials: Waterproof vs. Water-Repellent

Understanding the difference between waterproof and water-repellent is crucial. Specifically, these terms describe different levels of liquid protection:

Water-Repellent Aprons: These aprons feature a coating that causes water to bead up and roll off. However, they’re not completely impermeable. Therefore, they work well for light splash protection but won’t prevent soaking from prolonged exposure.

Waterproof Aprons: These aprons use PVC, polyurethane, or other impermeable materials. Consequently, they provide complete liquid barrier protection. Importantly, they’re essential for dishwashing stations, fish markets, and wet processing areas.

| Feature | Water-Repellent | Waterproof |

|---|---|---|

| Protection Level | Light splashes, brief exposure | Complete liquid barrier |

| Breathability | Moderate to good | Limited to none |

| Comfort | Good | Moderate (can be hot) |

| Applications | Cooking, food prep, bar service | Dishwashing, cleaning, wet processing |

| Price Point | Moderate | Low to moderate |

Chemical-Resistant and Heat-Resistant Options

Specialized environments require specialized protection. Therefore, consider these options for high-risk settings:

Chemical-Resistant Aprons: Laboratories, industrial kitchens, and manufacturing facilities often need aprons that resist acids, bases, or solvents. Specifically, polyethylene-coated fabrics or PVC aprons provide this protection. Additionally, always verify the specific chemicals your aprons will encounter and match materials accordingly.

Heat-Resistant Aprons: Grilling stations, pizza ovens, and metalworking areas require aprons with heat-resistant properties. Furthermore, materials like Kevlar or treated cotton offer protection up to specific temperature thresholds.

⚠️ Safety Note: Always request Material Safety Data Sheets (MSDS) and temperature rating documentation from your supplier. Moreover, ensure your aprons meet relevant OSHA safety standards for your specific industry.Material Performance Snapshot

| Material | Wash Cycle Rating | Stain Resistance | Comfort Score | Typical Cost per Unit |

|---|---|---|---|---|

| Cotton Twill | 50-75 cycles | Moderate | 9/10 | $12-18 |

| Poly-Cotton Blend | 100-150 cycles | High | 7/10 | $8-14 |

| 100% Cotton | 40-60 cycles | Low-Moderate | 10/10 | $15-25 |

| Canvas | 100+ cycles | High | 6/10 | $14-22 |

| PVC/Waterproof | 200+ cycles | Very High | 5/10 | $6-12 |

Sizing, Fit, and Ergonomics: Getting It Right for Your Team

Even the highest-quality apron fails if it doesn’t fit properly. Therefore, understanding sizing and ergonomic considerations ensures worker comfort and safety compliance.

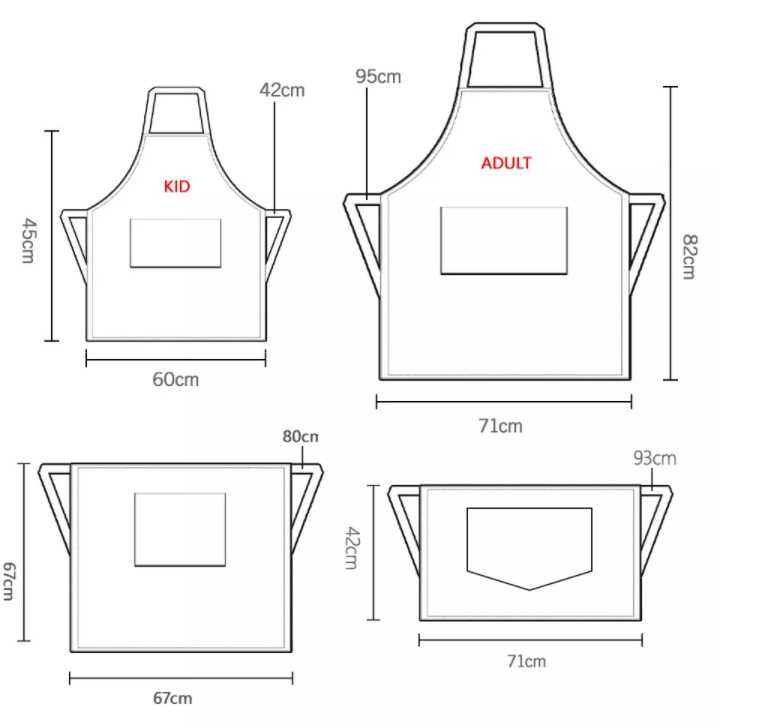

Professional apron sizing reference guide

Professional apron sizing reference guide

Adjustable strap systems for custom fit

Adjustable strap systems for custom fit

Properly fitted aprons improve worker comfort

Properly fitted aprons improve worker comfortHow to Choose Apron Sizes for Different Worker Roles

Different positions require different apron styles and sizes. Specifically, consider these role-based recommendations:

Executive Chefs and Line Cooks: Full bib aprons with 34-36″ length provide maximum coverage. Additionally, cross-back styles eliminate neck strain during 10+ hour shifts.

Prep Cooks and Bakers: Standard bib aprons (32-34″ length) offer protection without excessive bulk. Furthermore, multiple pockets help keep tools accessible.

Servers and Bartenders: Waist aprons or bistro-length aprons provide professional appearance without restricting upper body movement. Typically, 22-24″ length works best for most staff.

Dishwashers and Utility Staff: Waterproof full-coverage aprons protect against constant water exposure. Moreover, 36-38″ length provides maximum protection when bending or reaching.

Adjustable Features That Matter

Adjustability directly impacts worker satisfaction and apron longevity. Therefore, look for these critical features:

- Adjustable neck straps: Allow 4-6 inches of adjustment range

- Long waist ties: Minimum 30-inch ties accommodate various body types

- Cross-back designs: Eliminate neck pressure entirely

- Quick-release buckles: Enable fast removal in emergency situations

- Reinforced adjustment points: Prevent strap separation at grommets

Pocket Placement and Functionality

Pocket design significantly affects apron functionality. Moreover, well-designed pockets keep essential tools accessible without creating bulk or weight imbalance.

Optimal Pocket Configurations:

- Chest pocket: Ideal for thermometers, pens, or order pads

- Waist-level pockets: Perfect for towels, utensils, or phones

- Lower front pockets: Suited for larger tools or multiple items

- Divided pockets: Keep items separated and organized

- Reinforced pocket corners: Prevent tearing from heavy items

Coverage Considerations by Industry

Different industries require different coverage levels. Consequently, selecting appropriate length and width ensures proper protection:

| Industry | Recommended Length | Style | Key Features |

|---|---|---|---|

| Fine Dining | 32-34″ | Bib or cross-back | Premium materials, elegant appearance |

| Casual Restaurants | 30-32″ | Bib or waist | Durable blends, multiple pockets |

| Healthcare | 28-30″ | Cobbler or bib | Antimicrobial treatment, easy-clean |

| Industrial/Workshop | 36-42″ | Full coverage, cobbler | Heavy-duty canvas, tool loops |

| Retail/Craft | 28-32″ | Waist or pinafore | Attractive design, branding-friendly |

Customization and Branding: Making Your Mark Without Sacrificing Quality

Custom branded aprons serve dual purposes. Specifically, they protect workers while promoting your brand. However, customization must never compromise durability or functionality.

Logo Printing Methods: Embroidery vs. Screen Printing vs. Digital Printing

Each printing method offers distinct advantages. Therefore, choosing the right technique depends on your design complexity, budget, and volume requirements.

Embroidery:

- Advantages: Premium appearance, extremely durable (lasts lifetime of apron), professional texture, excellent for simple logos

- Considerations: Higher per-unit cost, limited to simpler designs, adds slight bulk

- Best for: Upscale restaurants, corporate gifts, long-term brand investment

- Typical cost: $3-8 per apron depending on design complexity

Screen Printing:

- Advantages: Cost-effective for large runs, vibrant colors, smooth finish, faster production

- Considerations: Less durable than embroidery, may crack after 50+ washes, setup fees for multiple colors

- Best for: Large orders (200+ units), simple color designs, budget-conscious buyers

- Typical cost: $1.50-4 per apron for standard designs

Digital Printing (DTG):

- Advantages: No minimum order quantity, perfect for complex designs, full-color capability, fast turnaround

- Considerations: Higher per-unit cost for large volumes, durability varies by fabric type

- Best for: Small orders, testing designs, photographic images, complex artwork

- Typical cost: $4-10 per apron depending on design size

“At Favor Houseware, we offer digital printing with no MOQ requirements. This flexibility allows businesses to test designs or order small quantities without committing to large production runs.” – Favor Houseware Customization Team

How to Maintain Durability with Custom Branding

Customization should enhance, not compromise, your aprons. Therefore, follow these guidelines to ensure branded aprons maintain quality:

- Use colorfastdyes: Specify colorfast printing to prevent fading during washing

- Reinforce print areas: Add backing material under prints to prevent cracking

- Strategic placement: Position logos away from high-wear areas like pocket edges

- Test washing protocols: Request wash-tested samples before bulk production

- Choose compatible methods: Match printing technique to fabric type

Views: 2