🚀 Quick Stats: Microfiber Towel Market in 2025

Microfiber Towel Trends 2025: Market Insights & Innovations from China Manufacturers

Microfiber towels are changing how we clean, dry, and care for surfaces in 2025. Moreover, the microfiber towel market is growing rapidly because buyers want products that work better while being kinder to our planet. In fact, new technologies are making these towels more powerful than ever before.

Whether you’re a business looking for microfiber cleaning innovations or a buyer searching for new microfiber towels, this guide will show you exactly what’s happening in 2025. Furthermore, we’ll share real market data, compare performance numbers, and explain why China manufacturers are leading the way in microfiber technology.

Microfiber Towel Trends 2025: What Buyers Really Want

The biggest microfiber towel trends 2025 focus on three main areas: sustainability, hygiene, and performance. As a result, manufacturers are responding with innovative solutions that meet these demands.

- Eco-friendly materials: Recycled RPET fibers reduce plastic waste significantly

- Antimicrobial protection: Silver-ion treatments keep towels fresh longer

- Specialized designs: Quick-dry, sand-resistant, and ultra-plush options for different needs

Consequently, these trends are not just passing fads. Instead, they represent real changes in how people think about cleaning products and environmental responsibility.

Key Microfiber Towel Innovations in 2025

| Innovation Type | Example Feature | Buyer Benefit |

|---|---|---|

| Eco Materials | Recycled RPET microfiber yarn | Lower plastic waste, supports ESG goals |

| Antimicrobial Treatments | Silver-ion infused fibers | Odor control, added hygiene |

| High-Density Split Fibers | Finer splits, higher GSM | Stronger absorbency and dirt capture |

| Hybrid Weaves | Twist-loop drying towels | Faster drying, streak-free finish |

| Quick-Dry, Sand-Resistant | Advanced microfiber beach/pool towels | Better guest experience; faster laundry cycles |

| Scrubber Integration | Dual-sided towels with scrub zones | One cloth for scrub + wipe |

| Smart Tracking | Washable RFID tags in cloths | Inventory and usage tracking in B2B |

Sustainability: Recycled RPET and Low-Chemical Cleaning

Sustainability is no longer optional in 2025. Therefore, manufacturers are increasingly using recycled RPET (polyethylene terephthalate) to create recycled microfiber towels from post-consumer plastic bottles. Additionally, this process reduces landfill waste while creating high-performance cleaning products.

Furthermore, microfiber technology allows cleaning with just water. As a result, facilities can dramatically cut chemical usage, which helps both the environment and worker safety. According to EPA guidelines, reducing chemical cleaners improves indoor air quality and reduces water pollution.

“One microfiber cloth can replace up to 1,500 disposable paper towels over its lifetime, making it a powerful tool for waste reduction.”

Antimicrobial and Odor-Control Microfiber Towels

Hygiene concerns remain high after the pandemic. Consequently, antimicrobial microfiber towels with silver-ion technology are gaining popularity. In fact, these treatments prevent bacterial growth between washes, which keeps towels fresher longer.

Moreover, this innovation is especially valuable in gyms, hotels, and healthcare facilities where towels are used frequently. Similarly, home users appreciate towels that stay fresh even in humid bathrooms or hot cars.

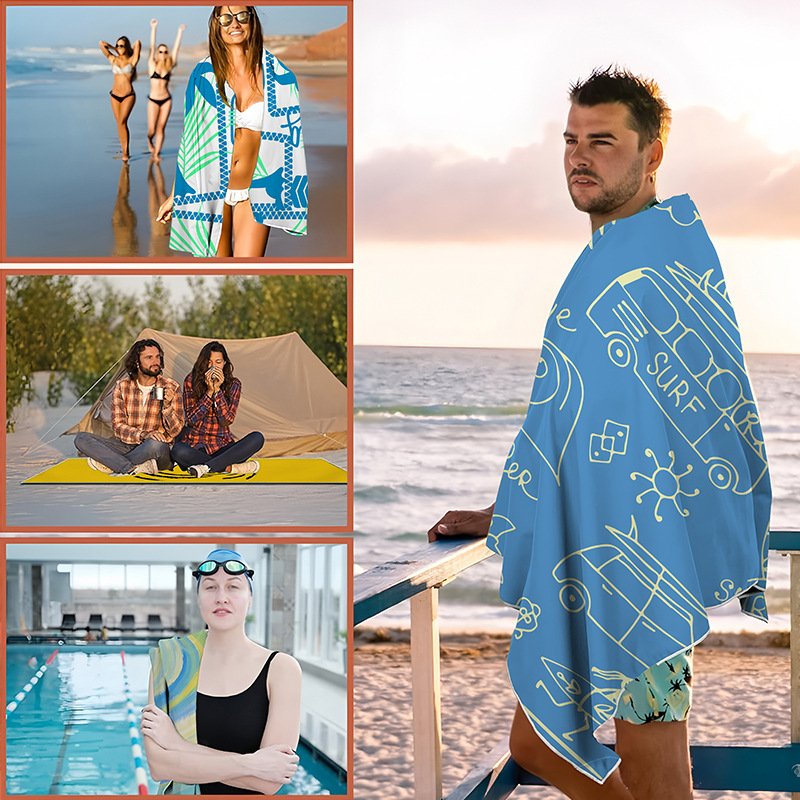

Quick-Dry and Sand-Resistant Beach & Pool Towels

Hospitality properties are upgrading their beach towels with advanced microfiber technology. Specifically, these new microfiber towels dry 3-5 times faster than traditional cotton, which reduces laundry costs and energy use.

Additionally, sand-resistant microfiber constructions shake clean easily, preventing the gritty texture guests dislike. Therefore, hotels and resorts are switching to these innovative towels to improve guest satisfaction while cutting operational costs.

Global Microfiber Towel Market Outlook in 2025

The microfiber towel industry is experiencing impressive growth worldwide. In particular, the cleaning cloth segment is expanding rapidly as more businesses and households discover the benefits of microfiber technology.

Understanding market trends helps buyers make smarter purchasing decisions. Therefore, let’s examine the numbers that show where this industry is headed.

Microfiber Towel & Cloth Market Snapshot 2025

| Metric | 2025 Value / Forecast | Source Note |

|---|---|---|

| Microfiber cleaning cloth market size | ~USD 979.2 million in 2025 | Global estimate |

| Alternate 2025 value (other study) | USD 883.8 million in 2025 | Different methodology |

| Cloth market CAGR 2025-2035 | 4.5% CAGR | Moderate growth |

| Cloth market CAGR 2025-2033 | 22.5% CAGR | High-growth scenario |

| Cloth market CAGR 2025-2032 | 11.2% CAGR | Additional forecast |

| Household revenue share 2025 | ~40% of cloth market | Home cleaning |

| Total microfiber products market 2025 | ~USD 7.5 billion; 6.3% CAGR | Broader product scope |

| Ultra-plush microfiber towel CAGR | ~13.6% CAGR 2025-2032 | Premium segment |

How Fast Is the Microfiber Cleaning Cloth Market Growing?

Different research firms report varying growth rates because they measure different market segments. However, all forecasts agree on one thing: the microfiber market is expanding rapidly.

For example, conservative estimates show a 4.5% CAGR through 2035, while more optimistic projections suggest 22.5% CAGR through 2033. In reality, growth rates vary by region and application, but the overall trend is clearly upward.

Moreover, the premium segment is growing even faster. Specifically, ultra-plush microfiber towels are projected to grow at approximately 13.6% CAGR through 2032, which shows strong demand for high-quality products.

Key End-Use Segments: Household, Commercial, Industrial

The microfiber market serves three main sectors, each with unique needs:

- Household (40% of market): Home cleaning, kitchen towels, bathroom care, and general wiping needs

- Commercial (35% of market): Hotels, restaurants, gyms, salons using microfiber for cost savings and hygiene

- Industrial (25% of market): Manufacturing facilities, healthcare institutions, and professional cleaning services requiring heavy-duty performance

Furthermore, the commercial and industrial segments are growing faster than household. This is because businesses recognize the long-term cost savings and environmental benefits of switching to microfiber systems.

According to research from ISSA (The Worldwide Cleaning Industry Association), facilities that switch to microfiber systems typically see ROI within 6-12 months through reduced supply costs and labor efficiency.

New Microfiber Towels: Materials, Constructions, and GSM Ranges

Understanding microfiber technology helps buyers choose the right products. Therefore, let’s explore how these innovative towels are made and what makes them special.

Split Microfiber and High-Density Weaves Explained

Microfiber towels work differently than regular cotton towels. Specifically, microfiber is made from extremely thin synthetic fibers that are “split” during manufacturing. As a result, each fiber becomes like a tiny claw with hundreds of edges.

Think of it this way: if a human hair is one unit of thickness, then a microfiber strand is 1/100th that size. Additionally, when manufacturers split these fibers, they create millions of micro-hooks that grab dirt, dust, and bacteria.

- Synthetic fibers (polyester and polyamide) are extruded together

- Chemical or mechanical processes split the fibers into star-shaped cross-sections

- This creates up to 200,000 fibers per square inch

- The increased surface area traps particles and absorbs liquid more effectively

Moreover, high-density weaves pack more of these split fibers into each square inch. Consequently, premium microfiber towels can hold 7 times their weight in liquid, compared to just 2-3 times for regular cotton.

Popular GSM Ranges for Cleaning, Auto, and Hospitality Towels

GSM (grams per square meter) measures fabric weight and density. In general, higher GSM means a thicker, more absorbent towel. However, different applications require different GSM ranges:

| Application | Recommended GSM | Best For |

|---|---|---|

| Glass & Window Cleaning | 180-250 GSM | Streak-free shine, lint-free results |

| General Cleaning Cloths | 250-300 GSM | All-purpose wiping, dusting, light cleaning |

| Automotive Detailing | 300-400 GSM | Paint-safe drying, polishing, waxing |

| Kitchen & Bath Towels | 350-450 GSM | High absorbency, daily household use |

| Ultra-Plush Premium | 450-600+ GSM | Luxury feel, spa quality, gift sets |

Furthermore, disposable microfiber options typically range from 180-220 GSM for cost-effective, single-use or limited-use applications.

Microfiber vs Traditional Towels in 2025: Performance and Sustainability

Many people wonder if microfiber really works better than cotton or paper. Therefore, let’s compare the actual performance numbers to see the difference.

Microfiber vs Traditional Cleaning Materials (2025)

| Metric | Microfiber Towel/Cloth | Cotton/Paper Alternatives |

|---|---|---|

| Bacteria Removal (with water) | Up to 98-99% | Around 30% in some tests |

| Absorbency | ≈7× own weight in liquid | Typically 2-3× for cotton; low for paper |

| Typical Lifespan | 300-500 washes | Single-use (paper) / far fewer washes |

| Paper Towel Replacement | 1 cloth ≈ 1,500 paper towels | — |

| Supply Cost Impact | ≈60% lower annual supply cost | Baseline |

Absorbency, Drying Time, and Bacteria Removal

Microfiber’s split-fiber structure creates exceptional cleaning performance. In particular, studies show that quality microfiber removes 98-99% of bacteria from surfaces using only water. In contrast, cotton cloths typically remove only about 30% under similar conditions.

Additionally, microfiber’s absorbency is remarkable. Because the split fibers create capillary action, microfiber can hold approximately 7 times its weight in liquid. Therefore, fewer towels are needed for drying tasks, which saves time and labor.

Moreover, microfiber dries faster than cotton. Specifically, the thin fibers and open weave structure allow air to circulate freely. As a result, microfiber towels dry in about half the time of cotton towels, which prevents mildew and odors.

“The capillary action in split microfiber is like having millions of tiny straws that pull liquid and dirt into the fabric, rather than just pushing it around the surface.”

Waste Reduction and ESG Targets

Sustainability is a major driver of microfiber adoption in 2025. Specifically, companies are discovering that switching to reusable microfiber helps meet Environmental, Social, and Governance (ESG) targets.

Consider these impressive numbers:

- Paper towel replacement: One quality microfiber cloth replaces approximately 1,500 disposable paper towels over its lifetime

- Waste reduction: A facility using 100 microfiber cloths can eliminate roughly 150,000 paper towels annually from landfills

- Cost savings: Businesses report approximately 60% reduction in annual cleaning supply costs after switching to microfiber systems

- Water conservation: Chemical-free cleaning with microfiber reduces wastewater contamination significantly

Furthermore, many China manufacturers now offer carbon-neutral production options and take-back programs for worn towels. Therefore, the environmental benefits extend throughout the entire product lifecycle.

According to the Green Cleaning Council, switching to microfiber is one of the most impactful changes facilities can make to reduce their environmental footprint.

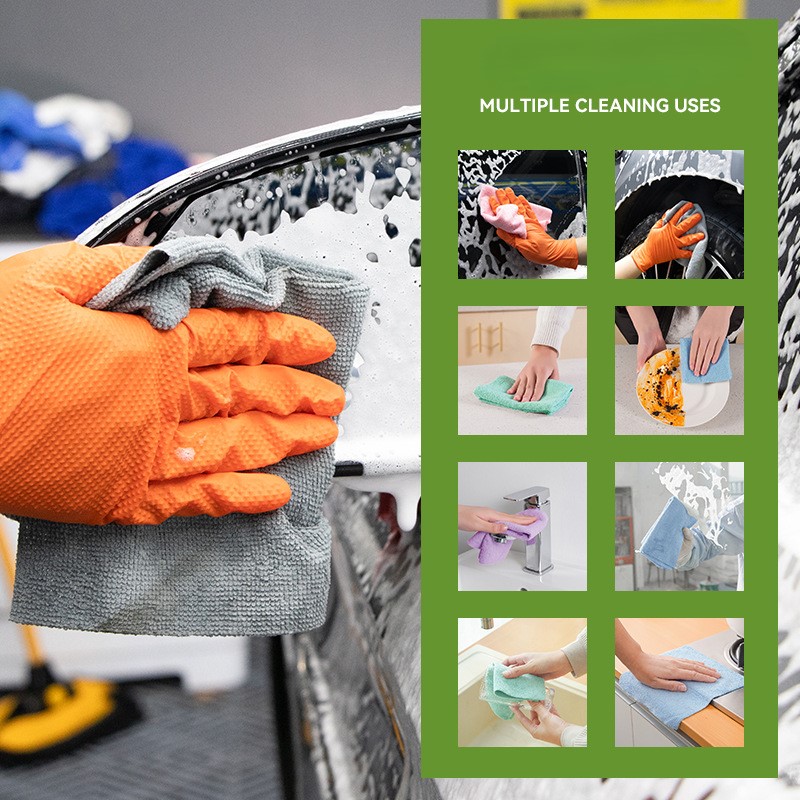

Microfiber Cleaning Innovations for Professional Use

Professional cleaning operations have different requirements than home users. Therefore, manufacturers have developed specialized microfiber cleaning innovations that meet the demanding needs of commercial and institutional facilities.

99% Bacteria Removal with Water-Only Cleaning

One of the most revolutionary aspects of modern microfiber is its ability to clean effectively without chemicals. In fact, the mechanical action of split microfibers removes up to 99% of bacteria from surfaces using only water.

This capability is especially valuable in sensitive environments:

- Healthcare facilities: Hospitals use microfiber to reduce chemical exposure for patients and staff while maintaining strict hygiene standards

- Food service: Restaurants appreciate chemical-free cleaning near food preparation areas

- Schools: Educational facilities protect children from harsh cleaning chemicals while maintaining cleanliness

- Hotels: Properties can clean guest rooms without strong chemical odors that guests dislike

Moreover, studies from CDC environmental cleaning guidelines confirm that proper microfiber systems match or exceed the effectiveness of traditional chemical cleaning for routine maintenance.

Smart Microfiber: RFID Tags, Color-Coding, and Process Control

Technology is transforming how facilities manage their microfiber inventory. Specifically, several innovative systems help ensure proper usage and tracking:

- RFID tracking: Washable chips embedded in towels track usage, location, and wash cycles automatically

- Color-coding systems: Different colors designated for specific areas prevent cross-contamination (red for bathrooms, blue for glass, green for food areas, yellow for general cleaning)

- Usage monitoring: Software systems alert managers when towels need replacement based on actual wash counts

- Quality control: RFID systems can identify when towels have degraded below performance standards

Furthermore, these systems help facilities meet compliance requirements. For instance, healthcare facilities can document that bathroom cleaning cloths never touch food preparation areas, which satisfies infection control audits.

Additionally, smart tracking reduces losses. Because facilities can monitor towel location and movement, inventory shrinkage typically drops by 30-40% after implementing RFID systems.

Eco and Cost Benefits: Why Companies Are Switching to Microfiber

The business case for microfiber is compelling. Therefore, more companies are making the switch from disposable cleaning products to reusable microfiber systems. Let’s examine the financial and environmental benefits.

Replacing Up to 1,500 Paper Towels with One Microfiber Cloth

The mathematics of microfiber make sense for both budgets and the environment. Specifically, one quality microfiber cleaning cloth can replace approximately 1,500 disposable paper towels over its usable lifetime.

Here’s how the numbers work out:

- Average paper towel cost: $0.02-0.03 per sheet

- Microfiber cloth cost: $2-5 per cloth (depending on quality and order volume)

- Lifespan: 300-500 wash cycles

- Paper towel equivalent: 1,500-2,000 sheets replaced

- Net savings: $25-40 per cloth over lifetime

Moreover, these savings multiply across an entire facility. For example, a hotel with 100 rooms might use 50,000 paper towels monthly for housekeeping. By switching to 200 microfiber cloths, they could save approximately $15,000-20,000 annually on paper products alone.

Additionally, businesses save on waste disposal costs. Because microfiber eliminates thousands of pounds of paper waste, facilities reduce trash hauling fees and dumpster rental costs significantly.

300-500 Wash Lifespan and ROI for B2B Buyers

Quality microfiber towels are designed to withstand 300-500 industrial wash cycles while maintaining performance. Therefore, the return on investment (ROI) for business buyers is exceptional.

Let’s calculate a simple ROI example for a commercial cleaning company:

| Factor | Paper Towel System (Annual) | Microfiber System (Annual) |

|---|---|---|

| Initial Investment | $0 (ongoing purchase) | $1,000 (200 cloths @ $5 each) |

| Monthly Supply Cost | $500 paper towels + $200 chemicals | $50 replacement cloths + $80 chemicals |

| Annual Supply Cost | $8,400 | $1,560 |

| Labor Efficiency | Baseline | 15% faster (better absorbency) |

| Waste Disposal Savings | $0 | $600/year |

| First Year Net Savings | — | $6,440 |

Furthermore, the ROI improves in subsequent years because the initial investment is already recovered. In fact, most facilities achieve payback within 2-4 months of switching to microfiber systems.

Moreover, additional benefits increase the value proposition:

- Reduced worker injuries: Less lifting of heavy boxes of paper products

- Storage savings: Microfiber requires less warehouse space than bulky paper supplies

- Brand reputation: Green cleaning programs attract environmentally conscious customers

- Compliance advantages: Meeting LEED and other green building standards becomes easier

According to analysis by Facilities Management industry research, microfiber systems typically deliver 300-600% ROI over a 5-year period.

How China Manufacturers Are Upgrading Microfiber Towels in 2025

China’s textile manufacturing industry continues to lead global microfiber innovation. Specifically, leading manufacturers are investing heavily in technology, sustainability, and quality control to meet international standards.

Recycled Yarn, OEKO-TEX, and ISO-Ready Production

Quality certifications have become essential for export-oriented manufacturers. Therefore, progressive Chinese factories are implementing comprehensive quality and environmental management systems.

- OEKO-TEX Standard 100: Guarantees textiles are free from harmful substances and safe for human use

- ISO 9001: Quality management system ensuring consistent product standards

- ISO 14001: Environmental management certification demonstrating sustainable practices

- GRS (Global Recycled Standard): Verifies recycled content in products and tracks chain of custody

- BSCI (Business Social Compliance Initiative): Ensures ethical labor practices and working conditions

Furthermore, many manufacturers now offer recycled microfiber products made from post-consumer plastic bottles. In fact, this recycling process diverts plastic waste from oceans and landfills while creating high-performance textiles.

Additionally, advanced Chinese factories invest in:

- Automated splitting technology: Computer-controlled processes ensure consistent fiber quality

- Water recycling systems: Closed-loop dyeing reduces water consumption by 40-60%

- Solar power integration: Renewable energy reduces carbon footprint of production

- Laboratory testing: In-house labs verify GSM, absorbency, colorfastness, and durability before shipment

According to a study on China manufacturing capabilities, top-tier textile manufacturers in China now match or exceed international quality standards while maintaining competitive pricing.

Custom Sizes, GSM, and Branding Options for Global OEM Orders

Flexibility is a major advantage of working with experienced Chinese microfiber manufacturers. In particular, professional OEM/ODM suppliers can customize nearly every aspect of microfiber products:

| Customization Type | Available Options | Typical MOQ |

|---|---|---|

| Size & Shape | Any dimensions, square, rectangular, round | 500-1,000 pieces |

| GSM Weight | 180-600+ GSM available | 1,000-3,000 pieces |

| Color | Pantone matching, custom dyeing | 500-2,000 pieces per color |

| Edge Finishing | Overlock, ultrasonic cut, folded hem | Varies by technique |

| Branding | Embroidery, screen print, woven labels, heat transfer | 500-1,000 pieces |

| Packaging | Polybag, box, display packaging, private label | Based on order size |

| Special Features | Antimicrobial treatment, RFID tags, dual-sided construction | 1,000-5,000 pieces |

Moreover, experienced manufacturers offer product development support. Therefore, brands can work with factory engineers to create unique microfiber products that differentiate them in the marketplace.

For example, Favor Houseware specializes in custom microfiber solutions for global brands, offering design consultation, sample development, and full production services with competitive lead times.

Additionally, many Chinese manufacturers maintain international sales offices and speak English fluently. As a result, communication and project management become much smoother for overseas buyers.

How to Choose the Right Microfiber Towel for Your Application

Selecting the correct microfiber product requires understanding your specific needs. Therefore, let’s explore recommendations for the most common applications to help you make informed decisions.

Glass and Stainless Steel Cleaning Towels

Glass and polished metal surfaces require special attention to avoid streaks and scratches. Consequently, the best microfiber towels for these applications have specific characteristics:

- GSM range: 180-250 GSM works best (lighter weight prevents streaking)

- Weave type: Tight, smooth weaves without texture or nap

- Edge finishing: Ultrasonic-cut or folded edges prevent scratching

- Fiber blend: Higher polyamide content (70-80%) improves streak-free results

- Color recommendation: Light colors (white, light blue) show dirt accumulation clearly

Furthermore, proper technique matters. For best results, clean glass with one slightly damp microfiber cloth, then polish dry with a second dry cloth. This two-cloth method ensures perfectly clear, streak-free glass every time.

Additionally, avoid fabric softeners when washing glass cleaning cloths. Because fabric softeners coat fibers with chemicals, they reduce the electrostatic attraction that makes microfiber effective on glass.

Automotive Detailing and Ultra-Plush Microfiber

Car enthusiasts and professional detailers have embraced microfiber because it’s safe for delicate automotive finishes. In particular, high-quality automotive microfiber prevents the swirl marks and scratches that traditional towels can cause.

- Drying towels: 400-600 GSM, twist-loop or waffle weave for maximum absorbency

- Polishing cloths: 300-400 GSM, ultra-soft plush surface

- Glass cleaning: 200-250 GSM, smooth weave

- Interior detailing: 250-350 GSM, medium pile height

- Wheel cleaning: 300-400 GSM, scrubbing texture acceptable

Moreover, edgeless designs are increasingly popular in auto detailing. Because traditional stitched edges can trap dirt particles and cause scratches, many detailers prefer ultrasonic-cut towels with no exposed seams.

Additionally, color matters in automotive applications. Dark-colored towels (black, gray, dark blue) hide dirt and stains better, which makes them ideal for wheels and exterior washing. Light colors work better for final drying and interior work where you need to see dirt clearly.

Professional detailers typically use 15-20 towels per vehicle to avoid cross-contamination. Therefore, bulk purchasing from manufacturers offers significant cost savings for auto care businesses.

Hospitality and Housekeeping Towels

Hotels, resorts, and vacation rentals have unique requirements for their towel programs. Specifically, they need products that balance guest comfort, durability, and operational efficiency.

For housekeeping operations, consider these categories:

| Towel Type | Recommended GSM | Best Applications |

|---|---|---|

| Guest Bath Towels | 400-500 GSM | Soft, absorbent, luxury feel for bathrooms |

| Pool/Beach Towels | 350-450 GSM | Quick-drying, sand-resistant, high turnover |

| Housekeeping Cleaning | 250-300 GSM | Multi-surface cleaning, color-coded systems |

| Kitchen Service | 300-350 GSM | Absorbent, heat-resistant for F&B operations |

| Spa/Salon Towels | 450-550 GSM | Ultra-plush, premium feel, frequent washing |

Furthermore, modern beach and pool towels use advanced microfiber technology that dries 3-5 times faster than cotton. As a result, hotels can reduce laundry cycle times and energy costs while improving guest satisfaction.

Additionally, hospitality buyers should consider these factors:

- Colorfastness: Commercial laundering requires excellent dye stability to maintain appearance

- Shrinkage resistance: Dimensional stability ensures towels maintain size through hundreds of washes

- Lint performance: Low-lint microfiber keeps laundry equipment cleaner and reduces maintenance

- Brand consistency: Work with manufacturers who can ensure consistent quality across multiple orders

Properties can also explore specialized options like Turkish hammam towels and surf poncho towels to differentiate their guest amenities and create memorable experiences.

Frequently Asked Questions About Microfiber Towels in 2025

In 2025, microfiber towel trends focus on sustainability, antimicrobial finishes, and higher-performance designs for both home and professional cleaning. Specifically, manufacturers are adding recycled fibers, odor-control treatments, and quick-dry, sand-resistant constructions for hospitality, auto, and fitness markets.

Yes, demand for microfiber cleaning towels continues to grow steadily worldwide. In fact, global microfiber cleaning cloth market estimates put 2025 value around USD 0.88-0.98 billion, with projected CAGRs between about 4.5% and 22.5% through 2032-2035 depending on segment and region.

Companies switch to microfiber because one reusable cloth can replace up to about 1,500 paper towels and last 300-500 wash cycles. Therefore, they cut both cost and waste significantly. Moreover, microfiber systems remove up to 98-99% of bacteria with water alone and have been shown to reduce annual supply costs by around 60% in some facilities.

New microfiber technology in 2025 includes recycled RPET yarns, antimicrobial fibers, higher-split microfilaments, and hybrid weaves that boost absorbency and durability. Additionally, some professional microfiber lines now use RFID tags and advanced color-coding to track inventory and enforce cleaning protocols in large facilities.

Microfiber towels are not biodegradable but can be more environmentally efficient than disposable paper or wipes when used correctly. Specifically, their long lifespan (hundreds of washes) and high cleaning efficiency significantly reduce solid waste and chemical usage. However, microplastic shedding means filters or wash bags are recommended during laundering.

Well-engineered microfiber towels can remove up to about 98-99% of surface bacteria using only water, thanks to split fibers and electrostatic attraction. In contrast, traditional cotton cloths may remove closer to 30% under similar test conditions. Therefore, microfiber is the preferred choice for hospitals, hotels, and professional cleaning services.

Lower GSM microfiber (around 180-250 GSM) is often used for general cleaning and glass where a lighter, streak-free cloth is needed. Meanwhile, mid to high GSM (300-500+ GSM) is preferred for auto detailing, drying, and plush household towels. Furthermore, ultra-plush microfiber towels in premium GSM ranges are a fast-growing niche with estimated double-digit CAGR through 2032.

Key sectors driving microfiber towel growth include household cleaning, hospitality, healthcare, automotive detailing, and industrial/commercial janitorial services. Specifically, household applications account for about 40% of microfiber cleaning cloth revenues, while hospitals and hotels adopt microfiber to meet higher hygiene and sustainability standards.

Hospitality beach and pool towels increasingly use advanced microfiber blends and hybrids that dry faster, feel lighter, and resist sand retention. Consequently, these quick-dry constructions help properties cut energy use in laundry while giving guests towels that feel dry within minutes and avoid mildew odors.

B2B buyers should check GSM, fiber blend, edge finishing, colorfastness, washing durability, and certifications such as OEKO-TEX or ISO-based quality systems. Furthermore, they should evaluate suppliers on their ability to offer recycled yarns, antimicrobial options, color-coding, private labeling, and consistent export logistics from China.

Conclusion: Partner with Expert China Microfiber Towel Manufacturers

The microfiber towel industry in 2025 offers tremendous opportunities for businesses seeking sustainable, high-performance cleaning solutions. As we’ve explored throughout this guide, microfiber towel trends 2025 are driven by sustainability, antimicrobial innovation, and specialized applications that deliver measurable cost savings and environmental benefits.

Key takeaways include:

- The global microfiber market is growing at 4.5-22.5% CAGR with strong demand across household, commercial, and industrial sectors

- New microfiber technologies include recycled RPET, antimicrobial treatments, smart tracking systems, and application-specific designs

- Microfiber delivers superior performance: 98-99% bacteria removal, 7x absorbency, and 60% cost reduction compared to disposables

- Quality China manufacturers now offer OEKO-TEX certification, ISO-compliant production, and full OEM/ODM customization

Moreover, choosing the right manufacturing partner is crucial for success. At Favor Houseware, we combine advanced production capabilities with comprehensive quality control and flexible customization options. Additionally, our commitment to sustainability includes recycled yarn options and eco-friendly production processes.

Ready to Source Premium Microfiber Towels?

Whether you need cleaning cloths, automotive towels, hospitality linens, or custom branded products, our experienced team can help bring your vision to life.

Get started today:

Request Free Samples Learn About Our Factory Read More Industry InsightsOur product range includes microfiber towels, kitchen towels, beach towels, and even complementary products like aprons and change robes for complete lifestyle solutions.

Contact us today to discuss your microfiber towel requirements and discover how we can support your business growth in 2025 and beyond.

Stay updated with the latest microfiber innovations and industry trends by visiting our blog regularly. We publish expert insights, product guides, and market analysis to help you make informed purchasing decisions.

Views: 2