Beach Towel Manufacturing: Complete Quality Control & Production Guide

| Production Stage | Process Description | Quality Checkpoint |

|---|---|---|

| Yarn Preparation | Selecting and preparing cotton or microfiber yarns | Fiber length, yarn strength, color consistency |

| Weaving | Creating terry fabric with warp and weft yarns | Loop uniformity, broken ends, weaving defects |

| Bleaching | Removing natural impurities from fabric | Whiteness level, fabric integrity |

| Dyeing/Printing | Adding color with computer color matching systems | Color accuracy, shade consistency, fastness |

| Finishing | Steaming, washing, shearing for softness | GSM weight, hand feel, absorbency rate |

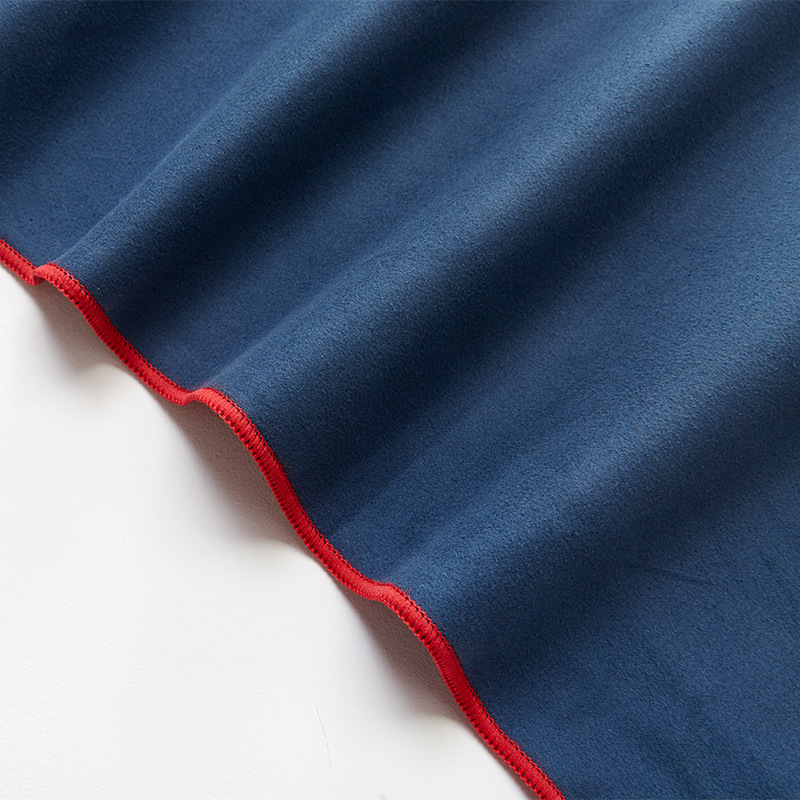

| Cutting & Sewing | Cutting to size and hemming edges | Dimensional accuracy, seam strength |

| Final Inspection | AQL-based sampling and testing | Overall quality, packaging standards |

Why Beach Towel Manufacturing Quality Matters in 2025

In today’s competitive textile market, beach towel manufacturers must maintain exceptional standards because buyers demand both quality and value. Furthermore, the global towel industry continues to experience steady growth, making quality control more important than ever for brands seeking reliable suppliers.

| Market Metric | Value |

|---|---|

| 2023 Market Size (Estimate) | ~USD 4.0 billion |

| 2024 Market Size (Broader Category) | ~USD 17.0 billion |

| 2033-2034 Forecast Size | USD 7.2-28.7 billion |

| Forecast CAGR | 5.4-5.9% |

| China’s Share in APAC Market | ~32% (2025) |

| Leading Region | Asia-Pacific |

Market estimates vary because analysts define towel categories differently. However, the clear trend shows steady 5-6% annual growth and China’s strong leadership role. Consequently, understanding the production process and quality control measures becomes essential for making informed sourcing decisions.

Key Steps in the Beach Towel Production Process

The beach towel production process involves seven critical stages. Moreover, each step requires precise control to ensure the final product meets international quality standards. Let’s explore how professional beach towel manufacturers transform raw materials into premium finished towels.

Step 1: Yarn Preparation and Material Selection

First, manufacturers select high-quality cotton or microfiber yarns based on the towel specifications. During this stage, quality teams check several important factors:

- Fiber length: Longer fibers create stronger, softer towels

- Yarn strength: Ensures durability through multiple wash cycles

- Color consistency: Prevents shading issues in the final product

- Cleanliness: Removes impurities that could cause defects later

Additionally, yarn preparation involves sizing, which coats the yarn to protect it during weaving. Therefore, this foundational step directly impacts the entire production process.

Step 2: Weaving Terry Fabric

Next, the prepared yarns move to specialized looms that create terry fabric. Essentially, terry weaving uses warp and weft yarns to form the characteristic loops that make towels absorbent. Professional beach towel manufacturers monitor several weaving parameters:

- Loop pile height: Controls absorbency and softness

- Fabric density: Determines towel weight (GSM) and durability

- Weaving tension: Prevents broken ends and streaks

- Pattern accuracy: Ensures consistent texture throughout

Similarly, advanced looms can create Turkish hammam towel patterns or jacquard designs. Thus, weaving technology directly affects both quality and design possibilities.

Step 3: Bleaching and Pre-Treatment

After weaving, the grey fabric undergoes bleaching to remove natural impurities. Specifically, this process creates a clean, white base that accepts dyes evenly. During bleaching, manufacturers carefully control:

- Chemical concentration: Removes impurities without damaging fibers

- Temperature settings: Optimizes cleaning while preserving fabric strength

- Treatment time: Ensures complete impurity removal

- Washing cycles: Eliminates residual chemicals before dyeing

Furthermore, proper bleaching prevents yellowing and ensures vibrant colors in the finished beach towels. Therefore, this pre-treatment stage is crucial for quality control.

Step 4: Dyeing and Printing with Color Matching

Subsequently, the bleached fabric enters the dyeing or printing stage. Modern beach towel manufacturers use computer color matching systems to achieve precise, consistent colors. This advanced technology offers several benefits:

- Exact shade reproduction: Matches brand Pantone colors perfectly

- Batch consistency: Ensures identical colors across production runs

- Recipe optimization: Reduces dye waste and environmental impact

- Quality documentation: Creates traceable color standards

Additionally, manufacturers can use reactive dyes for superior color fastness or apply screen printing for custom designs. Consequently, this flexibility allows brands to create unique beach towel products that stand out in the market.

Step 5: Finishing (Steaming, Washing, Shearing)

After dyeing, towels undergo finishing processes that enhance their final properties. Importantly, these treatments transform rough fabric into soft, absorbent beach towels. The finishing stage includes:

- Steaming: Sets colors and relaxes fabric tension

- Enzyme washing: Improves softness and hand feel

- Softener application: Enhances absorbency and comfort

- Shearing: Creates uniform pile height for consistent appearance

- Final washing: Removes excess chemicals and lint

Moreover, professional manufacturers test GSM (grams per square meter) during finishing to verify weight specifications. Therefore, this stage directly impacts customer satisfaction and product performance.

Step 6: Cutting and Sewing

Once finishing is complete, the fabric moves to the cutting department. Here, precision cutting machines slice the fabric according to exact specifications. Then, skilled operators sew the edges to prevent fraying. This stage requires careful attention to:

- Dimensional accuracy: Ensures towels meet size specifications

- Hem quality: Creates durable, neat edges that withstand washing

- Stitch density: Provides strength without creating bulky seams

- Label placement: Attaches care instructions and branding correctly

Similarly, some manufacturers like Favor-Houseware use automated sewing systems for consistent quality. Thus, combining skilled craftsmanship with technology delivers superior results in the production process.

Step 7: Final Inspection and Packaging

Finally, every towel undergoes thorough inspection before packaging. Professional beach towel manufacturers implement AQL (Acceptable Quality Limit) standards with random sampling. Inspectors check:

- Visual appearance: No stains, holes, or color defects

- Size accuracy: Dimensions match specifications

- Sewing quality: Strong, straight seams without loose threads

- Weight verification: GSM meets customer requirements

- Packaging standards: Proper folding, labeling, and protection

Additionally, manufacturers may conduct laboratory tests on sample towels from each batch. Consequently, this comprehensive quality control approach ensures only premium products reach customers.

How Professional Beach Towel Manufacturers Control Quality

Effective quality control separates professional beach towel manufacturers from basic suppliers. Furthermore, implementing systematic checks at every production stage prevents defects and ensures consistent output. Let’s examine how industry leaders maintain exceptional standards throughout the production process.

Raw Material Quality Checks

Before production begins, quality teams thoroughly inspect all incoming materials. Specifically, they verify that yarns, dyes, and chemicals meet predetermined specifications. This preventive approach includes:

- Fiber testing: Checking cotton staple length and microfiber denier

- Yarn strength analysis: Measuring tensile strength and twist uniformity

- Color verification: Ensuring dyes match required shades exactly

- Chemical purity checks: Confirming bleaching and finishing agents meet safety standards

Moreover, reputable suppliers provide certificates of analysis for all materials. Therefore, this documentation creates accountability and traceability throughout the supply chain. According to textile industry standards, raw material inspection prevents up to 70% of potential defects.

In-Process Monitoring (Weaving, Dyeing, Sewing)

During production, continuous monitoring catches issues before they multiply. Consequently, experienced beach towel manufacturers station quality inspectors at critical points throughout the factory. Their responsibilities include:

- Weaving inspection: Identifying broken ends, uneven pile, and tension problems immediately

- Dyeing surveillance: Monitoring color development and checking shade consistency every batch

- Printing verification: Ensuring pattern registration and color accuracy on printed designs

- Sewing oversight: Checking stitch quality, seam strength, and dimensional accuracy continuously

Additionally, modern factories use computer color matching systems to verify colors against approved standards. Similarly, automated measuring devices check fabric width and GSM throughout production. Thus, technology enhances human expertise in maintaining quality control.

Final Product Inspection (AQL Standards)

Before shipment, finished towels undergo comprehensive final inspection based on AQL (Acceptable Quality Limit) standards. Typically, professional manufacturers follow AQL 2.5 or stricter levels for export orders. The inspection process includes:

- Random sampling: Selecting towels from different production batches

- Critical defect checks: Rejecting any towels with holes, severe stains, or wrong dimensions

- Major defect assessment: Identifying color shading, uneven pile, or poor sewing

- Minor defect tolerance: Allowing small imperfections within AQL limits

- Documentation: Recording all findings in detailed inspection reports

Furthermore, many buyers hire third-party inspection companies to verify quality independently. Therefore, maintaining high internal standards ensures successful inspections and builds long-term customer trust. Companies like QIMA and SGS provide internationally recognized inspection services that validate manufacturer claims.

Industrial Standards and Lab Tests for Beach Towels

Professional beach towel manufacturers rely on standardized testing to verify product performance. Moreover, these scientific tests provide objective data that supports quality control decisions. Let’s explore the essential tests and certifications that define industry best practices.

Essential Laboratory Tests

- Water Absorbency Testing: This test measures how quickly and completely a towel absorbs water. Specifically, laboratories use ASTM D4772 standards to evaluate absorption rate and capacity. Consequently, high-quality beach towels should absorb their weight in water within seconds.

- Drying Time Measurements: Similarly, drying speed affects user satisfaction significantly. Therefore, manufacturers test how long towels take to dry completely under standard conditions. Typically, beach towels should dry within 4-6 hours in normal humidity.

- Color Fastness Tests: These critical tests verify that colors remain vibrant after exposure to washing, sunlight, and chlorine. Furthermore, professional testing includes:

- Wash fastness (ISO 105-C06): Simulates 40-50 home washes

- Light fastness (ISO 105-B02): Tests resistance to sun fading

- Chlorine fastness (ISO 105-E03): Checks durability in pool environments

- Shrinkage and Dimensional Stability: Quality towels maintain their size after washing. Consequently, manufacturers test shrinkage rates following ISO 5077 standards. Typically, shrinkage should stay below 5% after three wash cycles.

- Lint Shedding Assessment: Excessive lint frustrates customers and indicates poor quality. Therefore, laboratories conduct lint release tests to ensure towels shed minimal fibers during use and washing.

| Test Type | What It Measures | Industry Standard |

|---|---|---|

| Water Absorbency | Absorption speed and capacity | ASTM D4772 |

| Drying Time | Hours to complete dryness | 4-6 hours (standard conditions) |

| Color Fastness (Wash) | Color retention after washing | ISO 105-C06 (Grade 4-5) |

| Color Fastness (Light) | Resistance to sun fading | ISO 105-B02 (Grade 4 minimum) |

| Shrinkage | Size change after washing | ISO 5077 (≤5%) |

| Tensile Strength | Fabric tear resistance | ASTM D5034 (minimum 80N) |

Key Certifications (ISO 9001, OEKO-TEX, BSCI)

Beyond product testing, certifications demonstrate a manufacturer’s commitment to quality and safety. Therefore, buyers should verify that suppliers hold relevant certifications. The most important include:

- ISO 9001: This quality management certification proves manufacturers follow documented processes consistently. Furthermore, ISO 9001 certification requires regular audits and continuous improvement efforts.

- OEKO-TEX Standard 100: Importantly, this certification guarantees that towels are free from harmful chemicals and safe for human skin. Additionally, OEKO-TEX testing is especially crucial for products that contact skin directly, like beach towels.

- BSCI (Business Social Compliance Initiative): This audit verifies ethical manufacturing practices including fair labor conditions and environmental responsibility. Therefore, BSCI certification assures buyers that workers are treated fairly.

- GOTS (Global Organic Textile Standard): For organic cotton towels, GOTS certification confirms sustainable farming and processing methods throughout the supply chain.

Moreover, reputable beach towel manufacturers like Favor-Houseware maintain multiple certifications to meet diverse customer requirements. Consequently, these credentials provide assurance that the production process meets international standards for both quality and ethics.

Common Defects in Towel Production and How to Avoid Them

Understanding common defects helps buyers evaluate beach towel manufacturers and assess their quality control capabilities. Furthermore, knowing prevention methods reveals which suppliers implement truly effective systems. Let’s examine the most frequent issues and proven solutions.

| Defect Type | Root Cause | Prevention Method |

|---|---|---|

| Uneven Pile Height | Inconsistent loom tension or yarn quality variations | Regular loom calibration and strict yarn inspection |

| Weaving Faults | Broken warp ends, weft streaks, or mechanical issues | Real-time monitoring with automatic stop motions |

| Color Shading | Uneven dye penetration or batch mixing errors | Computer color matching and proper dye circulation |

| Poor Color Fastness | Wrong dye selection or insufficient fixation time | Laboratory testing and proper heat setting |

| Excessive Lint | Short fiber content or insufficient singeing | Quality fiber selection and double singeing process |

| Size Deviation | Cutting errors or high shrinkage rates | Pre-shrinking treatment and computerized cutting |

| Weak Seams | Low stitch density or incorrect thread tension | Regular sewing machine maintenance and operator training |

| Stains or Spots | Contamination during processing or storage | Clean production environment and fabric protection |

Additionally, prevention strategies work best when implemented systematically throughout the production process. For example, fabric inspection on grey cloth catches weaving defects before expensive dyeing. Similarly, strict dyeing and printing control prevents costly color issues. Moreover, standard wash tests verify colorfastness before bulk production begins.

Furthermore, implementing AQL-based final inspection with random sampling provides a final safety net. According to quality inspection standards, proper AQL application reduces customer complaints by over 80%. Therefore, comprehensive prevention combined with systematic inspection creates the most reliable quality control system.

Why Global Brands Source Beach Towels from China

China dominates global towel manufacturing for compelling strategic and economic reasons. Moreover, the country’s textile infrastructure has evolved into the world’s most comprehensive ecosystem. Let’s explore why international brands consistently choose Chinese beach towel manufacturers for their supply needs.

China’s Towel Manufacturing Advantages

The Chinese textile industry offers unique advantages that few other countries can match. Specifically, these benefits stem from decades of industrial development and ongoing investment in manufacturing capabilities:

- Integrated supply chain: Complete spinning, weaving, dyeing, and sewing clusters exist within close proximity, reducing transportation costs and lead times significantly

- Advanced technology: Modern factories invest heavily in computerized looms, automatic color matching systems, and quality testing equipment

- Skilled workforce: Generations of textile workers have developed specialized expertise in beach towel production techniques

- Scalable capacity: Manufacturers can easily adjust production volumes from small custom orders to massive retail contracts

- Quality certifications: Leading suppliers maintain international certifications including ISO 9001, OEKO-TEX, and BSCI standards

- Competitive pricing: Economies of scale and efficient operations enable cost-effective production without compromising quality

- Innovation capability: Chinese manufacturers rapidly adopt new technologies like

update beach_towel_seo_article - Innovation capability: Chinese manufacturers rapidly adopt new technologies like

- Innovation capability: Chinese manufacturers rapidly adopt new technologies like microfiber materials and recycled fabrics

- Innovation capability: Chinese manufacturers rapidly adopt new technologies like

Furthermore, according to research from TXM Consulting, China’s manufacturing efficiency delivers 20-30% cost advantages compared to Western production facilities. Therefore, brands can maintain profit margins while offering competitive retail prices.

Asia-Pacific Market Leadership Data

Statistical evidence clearly demonstrates Asia-Pacific’s dominance in towel manufacturing. Specifically, the region leads both production capacity and market growth projections:

- Market share: Asia-Pacific accounts for approximately 32% of the global towel market as of 2024

- Growth rate: The region experiences above 6% CAGR, outpacing global averages significantly

- Export leadership: China remains the world’s largest towel exporter, supplying major retailers across Europe, North America, and Australia

- Production concentration: Key manufacturing hubs in Jiangsu, Shandong, and Hebei provinces create specialized towel clusters

Additionally, this geographic concentration creates powerful network effects. For instance, yarn suppliers, dyeing facilities, and finishing specialists all operate nearby. Consequently, beach towel manufacturers can quickly source materials and solve production challenges efficiently.

Top 5 Reasons for China Sourcing

- Complete vertical integration: From raw cotton to finished packaged towels, everything happens within controlled supply chains that ensure quality and speed

- Flexible minimum orders: Unlike some manufacturers requiring huge minimums, Chinese suppliers often accommodate smaller trial orders for new brands

- Rapid sampling capability: Professional factories like Favor-Houseware produce custom samples within 7-10 days for design approval

- Diverse product range: Manufacturers offer various towel types including Turkish hammam towels, surf ponchos, and changing robes

- Established logistics networks: Experienced freight forwarders and shipping routes ensure reliable, cost-effective international delivery

Moreover, China’s infrastructure continues improving with initiatives focused on sustainable manufacturing. Therefore, brands concerned about environmental impact can find beach towel manufacturers committed to eco-friendly practices and certifications.

How Favor-Houseware Controls Quality for OEM/ODM Beach Towels

Understanding theoretical quality control principles matters, but seeing real-world implementation provides greater value. Therefore, let’s examine how Favor-Houseware applies industry best practices throughout their production process. This practical example demonstrates what buyers should expect from professional beach towel manufacturers.

Our 7-Stage Quality System

Favor-Houseware implements comprehensive quality control at every production stage. Specifically, our integrated approach catches potential issues early while maintaining efficiency. Here’s how each stage works in practice:

Stage 1 – Material Verification: Before production starts, our quality team tests all incoming cotton and microfiber materials. Additionally, we verify yarn strength exceeds minimum standards and check color consistency across batches.

Stage 2 – Weaving Monitoring: During fabric production, inspectors conduct hourly checks on loom performance. Furthermore, we measure pile height uniformity and immediately address any tension inconsistencies.

Stage 3 – Dyeing Control: Our computer color matching system ensures perfect shade reproduction every time. Similarly, we test color fastness on sample pieces before processing full batches.

Stage 4 – Printing Inspection: For custom designs, we verify pattern registration and color accuracy on test prints first. Consequently, this prevents costly errors in bulk production runs.

Stage 5 – Finishing Verification: After washing and softening, we test absorbency rates and measure actual GSM against specifications. Therefore, customers receive towels that perform exactly as promised.

Stage 6 – Sewing Quality: Our trained operators check stitch density and seam strength continuously throughout production. Additionally, supervisors conduct random inspections every hour.

Stage 7 – Final AQL Inspection: Before shipment, we implement strict AQL 2.5 standards with statistical sampling. Moreover, detailed inspection reports document all findings for customer transparency.

Certifications and Compliance

Favor-Houseware maintains multiple international certifications that validate our quality control commitment. Specifically, we hold:

- ISO 9001:2015: Certified quality management system with annual audits ensuring continuous improvement

- OEKO-TEX Standard 100: All our beach towels are tested free from harmful substances

- BSCI Compliance: Regular social audits verify ethical labor practices and safe working conditions

- Sedex Membership: Transparent supply chain data available for customer due diligence

Furthermore, these certifications aren’t just certificates on walls. Instead, they represent daily operational practices that our team follows rigorously. Consequently, customers can trust that every towel meets international safety and quality standards.

Custom Manufacturing Capabilities

Beyond standard beach towel production, Favor-Houseware offers extensive customization options for OEM and ODM clients. Specifically, our capabilities include:

- Design flexibility: From simple solid colors to complex jacquard patterns and full-color printing

- Size variations: Any dimensions from compact travel towels to oversized beach blankets

- Material options: 100% cotton terry, microfiber blends, or recycled materials

- Weight specifications: GSM ranging from lightweight 280 to premium 600 depending on application

- Special features: Sand-resistant technology, quick-dry treatments, or antimicrobial finishes

- Private labeling: Custom tags, packaging, and branding that matches your brand identity perfectly

Additionally, we also manufacture complementary products including kitchen towels, aprons, and other home textile items. Therefore, brands can consolidate suppliers and simplify their sourcing process.

Process Timeline

Transparency in scheduling helps buyers plan inventory effectively. Therefore, here’s our typical production timeline for custom beach towel orders:

- Days 1-3: Receive specifications, create initial samples, and conduct material sourcing

- Days 4-10: Produce and ship physical samples for customer approval and testing

- Days 11-14: Finalize artwork, color standards, and production specifications based on approved sample

- Days 15-40: Complete bulk production including weaving, dyeing, finishing, cutting, and sewing stages

- Days 41-45: Conduct final AQL inspection, prepare packing, and arrange shipping documentation

- Days 46-50: Load containers and dispatch shipment to customer’s designated port or warehouse

Moreover, we maintain constant communication throughout this timeline. Consequently, customers receive regular updates and can address any concerns promptly. Furthermore, our experienced team at Favor-Houseware has refined this process over years of international cooperation.

Frequently Asked Questions About Beach Towel Manufacturing

Beach towels are manufactured by weaving terry fabric from cotton or microfiber yarns, then bleaching, dyeing or printing, finishing, cutting, sewing, and packing. Specifically, each stage controls properties like softness, absorbency, color vibrancy, and durability so the final towel meets buyer specifications. Additionally, professional beach towel manufacturers implement quality control checkpoints throughout the production process to ensure consistency.

A good beach towel should pass tests for water absorbency, drying time, color fastness to washing and sunlight, shrinkage after laundering, and dimensional accuracy. Furthermore, many buyers also require checks on lint shedding and seam strength to ensure the towel stays soft, does not shed excessively, and withstands repeated washing. Moreover, professional manufacturers conduct these tests following international standards like ASTM D4772 for absorbency and ISO 105 for color fastness.

Reliable manufacturers usually have clear specifications (GSM, yarn type, size tolerances), a documented quality system such as ISO 9001, and a track record with export customers. Additionally, buyers often review certifications, inspect pre-production samples, and use third-party inspections or AQL standards to verify consistent quality before long-term cooperation. Therefore, checking references and visiting facilities provides the best assurance of manufacturer capabilities and reliability.

Lead time depends on order quantity, material availability, and printing method, but many factories quote 45-50 days from sample approval to shipment for custom designs. Specifically, time is needed for yarn preparation, weaving, dyeing or printing, finishing, sewing, and final inspection. Consequently, early sample approval and clear artwork help shorten the schedule significantly. Moreover, experienced beach towel manufacturers like Favor-Houseware maintain material inventory to accelerate production for repeat orders.

ISO 9001 quality management systems and textile safety standards such as OEKO-TEX are widely recognized by international buyers. Additionally, these frameworks support controlled processes, traceability, and assurance that towels meet both performance and safety expectations in export markets. Furthermore, ethical certifications like BSCI demonstrate commitment to fair labor practices. Therefore, choosing manufacturers with multiple relevant certifications reduces supply chain risks substantially.

How to Choose a Reliable Beach Towel Manufacturer

Selecting the right beach towel manufacturer significantly impacts product quality, brand reputation, and business profitability. Therefore, buyers should evaluate potential suppliers systematically using concrete criteria. This comprehensive checklist helps you make informed sourcing decisions with confidence.

- Verify certifications: Confirm ISO 9001, OEKO-TEX, and BSCI certifications are current and conduct independent verification when possible

- Review production capacity: Ensure the manufacturer can handle your order volumes without sacrificing quality or extending lead times unreasonably

- Examine sample quality: Request samples in your exact specifications and conduct thorough testing for absorbency, colorfastness, and durability

- Assess technical capabilities: Verify they have computer color matching systems, modern looms, and proper testing equipment for systematic quality control

- Check reference customers: Contact existing clients to understand real experiences with delivery reliability, quality consistency, and communication responsiveness

- Evaluate customization flexibility: Confirm they can accommodate your specific GSM requirements, printing methods, and special treatments

- Review quality documentation: Examine their production process documentation, inspection procedures, and AQL standards implementation

- Understand lead times: Clarify realistic timelines for sampling, bulk production, and peak season variations

- Assess communication quality: Professional manufacturers provide clear responses, detailed quotations, and proactive updates throughout production

- Verify material sourcing: Understand where they source yarns and chemicals to ensure supply chain transparency and sustainability

- Examine factory conditions: If possible, conduct facility visits or video tours to assess equipment, cleanliness, and working conditions

- Compare pricing structure: Beyond unit prices, evaluate payment terms, shipping arrangements, and any hidden costs in quotations

Furthermore, building long-term partnerships with reliable suppliers creates competitive advantages. For instance, established relationships often lead to better payment terms, priority production scheduling, and collaborative product development. Consequently, investing time in thorough supplier evaluation pays significant dividends over multiple order cycles.

Additionally, consider manufacturers who offer complementary products. For example, Favor-Houseware produces not only beach towels but also surf ponchos and changing robes. Therefore, consolidating suppliers simplifies logistics and strengthens negotiating positions for better pricing and terms.

Get Your Custom Beach Towels with Certified Quality

Partner with a trusted beach towel manufacturer that combines advanced technology, rigorous quality control, and decades of export experience. Favor-Houseware delivers premium towels that meet international standards while maintaining competitive pricing through efficient production processes.

Whether you need standard terry towels, specialized microfiber options, or sustainable recycled materials, our team provides solutions tailored to your exact requirements.

Request Sample Get Quote View CertificationsConclusion: Quality Manufacturing Makes the Difference

Understanding the complete beach towel production process empowers buyers to make informed sourcing decisions. Throughout this guide, we’ve explored how professional beach towel manufacturers implement systematic quality control at every stage—from raw material inspection through final AQL testing.

The key takeaways include recognizing that quality doesn’t happen by accident. Instead, it results from deliberate investment in technology like computer color matching systems, comprehensive testing protocols following international standards, and experienced teams dedicated to continuous improvement. Furthermore, certifications such as ISO 9001 and OEKO-TEX provide objective validation of manufacturer capabilities and commitments.

China’s dominance in towel manufacturing stems from decades of infrastructure development, vertical integration, and scale advantages. Consequently, the country’s approximately 32% market share in Asia-Pacific continues growing above 6% annually. Therefore, brands seeking reliable, cost-effective production naturally look to established Chinese suppliers with proven track records.

When evaluating potential partners, remember that the cheapest option rarely delivers the best value. Instead, focus on manufacturers who demonstrate transparent processes, maintain relevant certifications, and provide detailed quality documentation. Additionally, strong communication and flexibility in accommodating custom requirements often prove more valuable than minimal cost savings.

Whether you’re launching a new beach lifestyle brand, expanding existing product lines, or seeking to improve current supplier relationships, choosing the right beach towel manufacturer represents a critical business decision. Professional suppliers like Favor-Houseware combine manufacturing excellence with customer partnership approaches that support your long-term success.

Ready to experience the difference that certified quality and systematic production processes make? Our team stands ready to discuss your specific requirements, provide detailed samples, and demonstrate why leading brands trust us for their beach towel manufacturing needs. Visit our blog for more insights on textile manufacturing, or contact us today to start your custom towel project with confidence.

For more information about our complete product range including kitchen towels, hammam towels, and cleaning cloths, explore our website or speak with our product specialists who can recommend the best solutions for your specific market needs.

Views: 5